What is it like to work with the biggest column alembics?

We spoke with Louise and Bruce Bickerton of Blue Mountains Lavender about their set up, and how they get the best from their 100L column still.

Blue Mountains Lavender is the Bickerton’s 10-hectare farm in Hartley, NSW, Australia. They describe their business as ‘Grower-Distiller-Maker’ as they distil and craft all their products from what they grow themselves—while following sustainable and regenerative farming practices.

Lavender was a perfect fit with these principles, but importantly it also suited the land and the climate—which has helped the plants to survive both drought and bushfires since they were first planted in 2019.

They grow a range of lavender varieties (including both L. angustifolia and L. intermedia cultivars) which are harvested for either dry stripped buds or distillation into essential oil. From this Louise produces a range of body care, sleep aid and lifestyle products which are sold throughout the region.

The set up

The Bickertons consider their set up as ‘artisan’ rather than industrial-scale production, and credit this as being responsible for the quality of their lavender oil (which has won awards in both Australia and New Zealand).

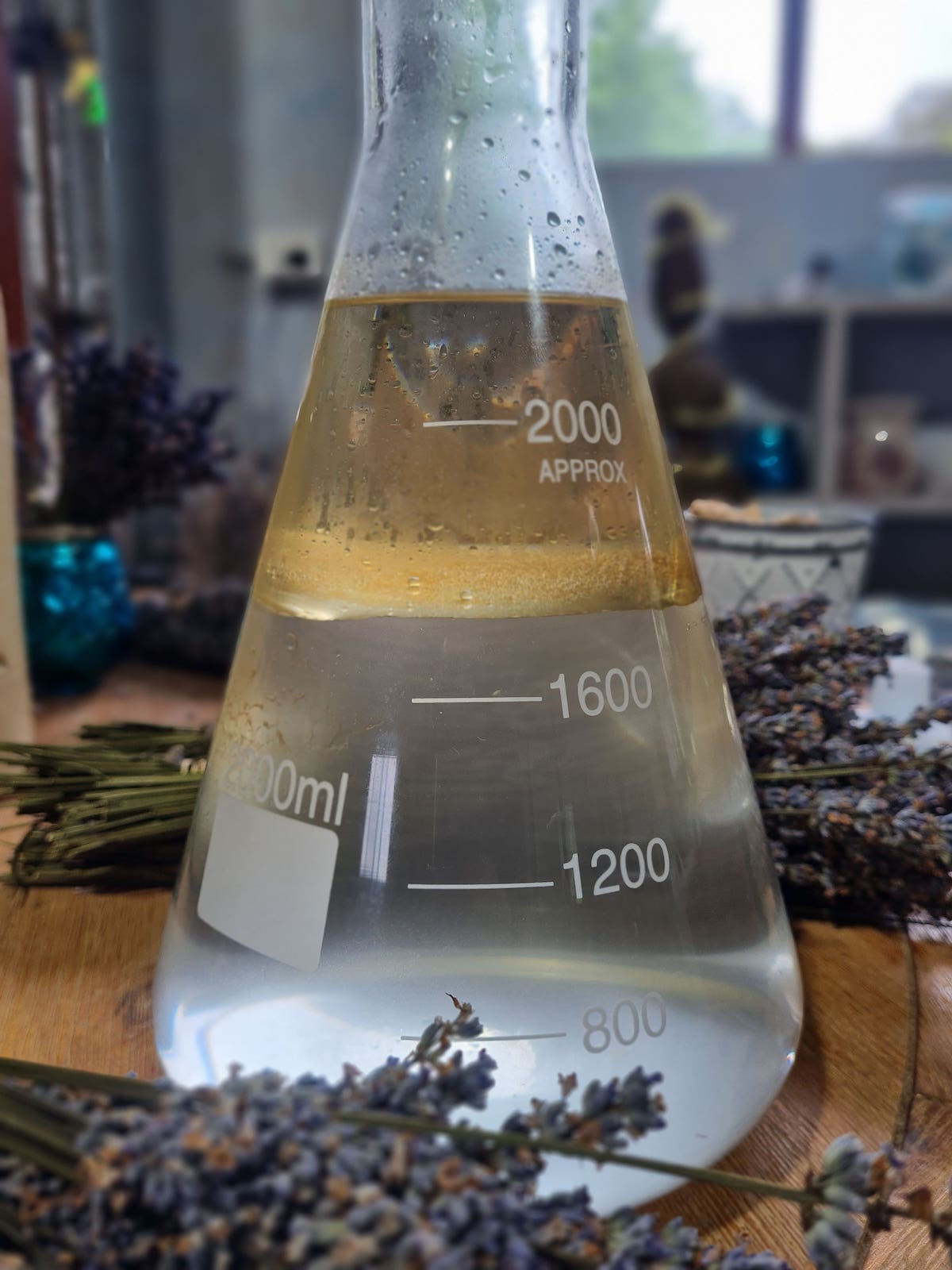

At the heart of their operation is the 100L copper alembic column still (dubbed ‘Jerry’ after the actor Jerry Stiller) which has pride of place in their processing shed. These large stills benefit from bespoke setups in order to run optimally—so the Bickertons have plumbed it into a system with gas fuel and filtered rainwater (with the latter being recycled for efficiency). This enables Bruce to manage multiple distillation sessions a day in the critical harvest weeks of mid-summer.

The exact time for optimal harvest depends on the plants and the weather. Plants are at their best for distilling when 50–60% of flowers have wilted, and the bee activity is over just before it goes to seed. And it’s best to harvest when it’s warm and dry, without any rainfall in the past week. Distillers need to seize this window of opportunity, and this setup ensures they’re ready to go when the plants are.

The distillation workspace

Flowers are harvested with approx. 10cm of stem attached.

Distillation and yields

Each fully-packed distillation run can take between 12–14kg of flower material and can yield between 240ml and 560ml of essential oil (a 2-4% yield) depending on the variety, harvest timing, bloom stage and distilling duration.

Louise and Bruce currently hand-harvest all their lavender, and can do two or three fully-charged runs in a day. This harvest season lasts 2-3 weeks—it’s a brief but intensive period of distilling for the year.

Each lavender variety is distilled separately, giving them the option of experimenting with blends (which is especially useful with lower-yielding varieties) and producing single-origin essential oils. Blue Mountain’s first winning oil was distilled from the cultivar L. x intermedia ‘Riverina Alan’ (in 2023 it won gold in the ‘Triploid’ category of the Olfactory Oil Competition conducted by The Australian Lavender Growers’ Association).

‘Riverina Alan’ blooms earlier than their other major variety, L. x intermedia ‘Grosso’ which is a late maturing plant. Grosso is a very popular variety grown in both NZ and Australia, and their 2023 harvest Grosso oil also recently won a Silver Certificate in the 2023 NZ Oil competition.

Apart from looking cool, Louise says their 100L copper still is fun and easy to work with—and they love that the essential oil produced is usable with minimal maturing. They’ve found that the copper neutralises many of the sulphuric compounds during the distillation process—as opposed to stainless steel which produces essential oil that needs to be stored away from light, in glass for many months before the true fragrance of the oil is revealed. While both metals will distil a lovely smelling oil, the oil from their copper still is ready to use almost immediately after separating from the hydrosol distillate water.

Bruce also has other, smaller copper stills which he uses to produce botanical hydrosols which they plan to release for sale in the future. Amongst them is ‘Ben’ the 5L column. Why? Because Ben is Jerry Stiller’s son. Bruce says very few people get the joke, but he’s not fussed.